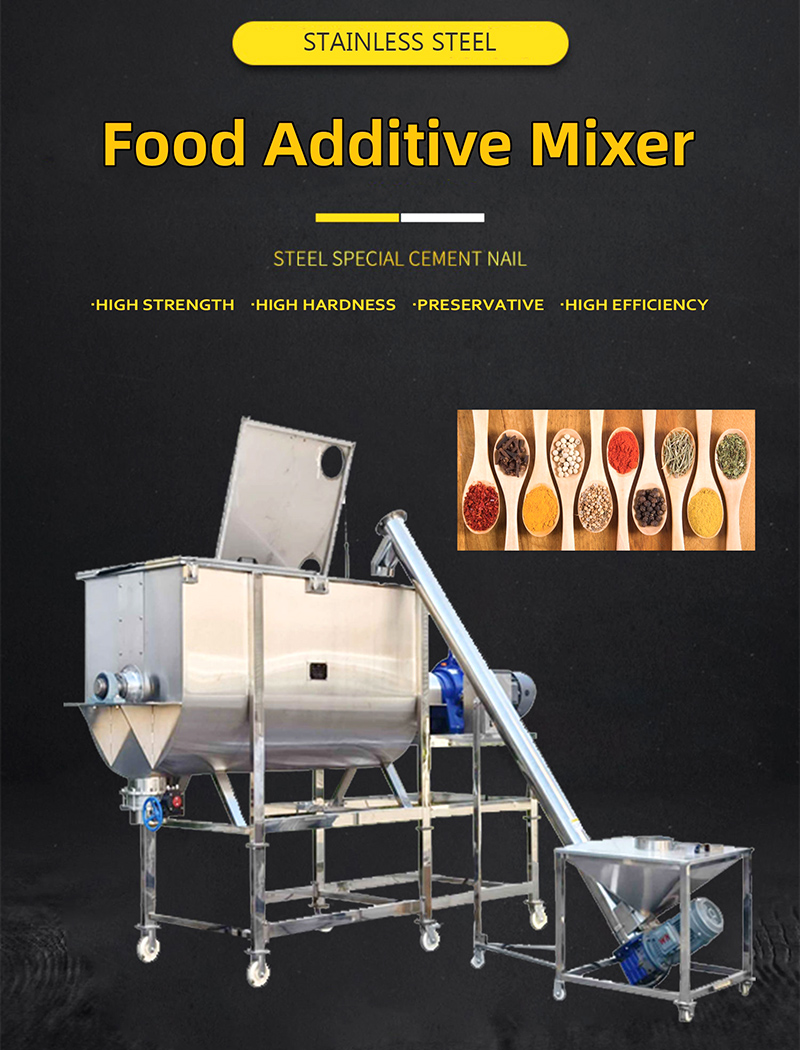

Equipment for effectively mixing and uniformly dispersing food additives to improve food quality and stability

![]()

![]()

Price::$1000.00-$7,000.00/Set

Consult now and enjoy a 10% discount

Mixing time: 8-20min

One-time mixing: 100-6000 (kg)

Mixing speed: 15-60r/min

Power: 3.5-75kw

Feeding method: manual feeding, automatic feeding or other methods

Discharging method: manual unloading, automatic unloading or other methods

Application: Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Construction works , Food & Beverage Shops

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Food Additive Mixer is a special equipment used to mix and evenly disperse different types of food additives. It usually uses advanced mixing technology and design to quickly and effectively mix additives with food base materials, ensuring uniform distribution and stability of additives. Such machines play a key role in food processing and production, improving the quality, taste and nutritional value of food.

Food additive mixers have different models and types, which can be reasonably selected according to actual production needs and product characteristics. Generally, stainless steel and high manganese steel can be used. They are corrosion-resistant and high-temperature resistant, easy to clean, clean and hygienic, and are widely used in the food industry, such as condiments, nutritional products and other fields.

Food additive mixers can be divided into the following four types according to their working principles, features and applications:

| Types | Food additive drum mixer | Food additive ribbon mixer | Food additive paddle mixer | Food Additive V-type Mixer |

| Picture |  |

|

|

|

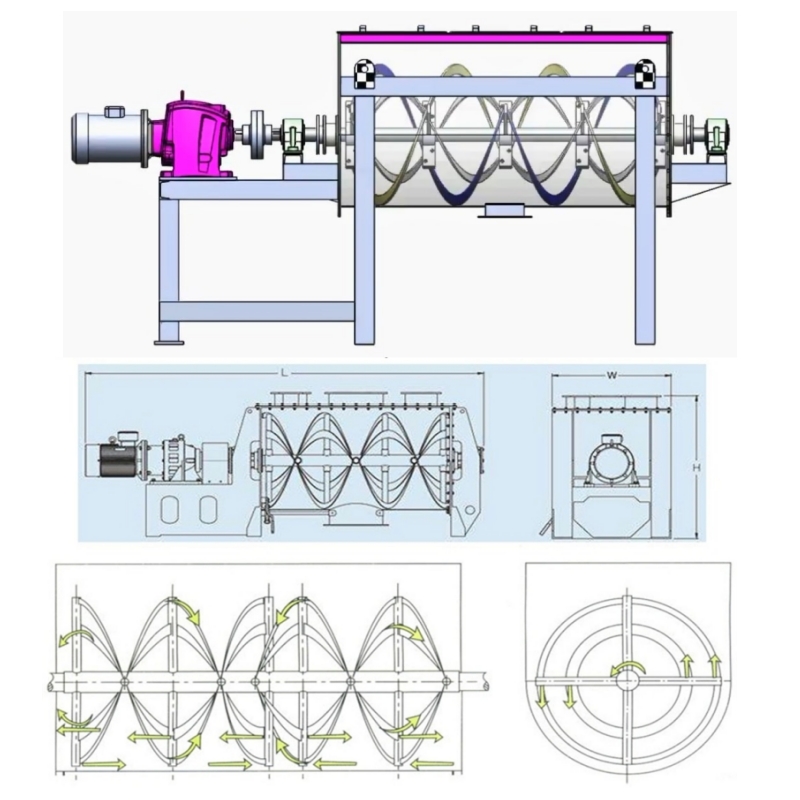

| Working principle | The drum mixer mixes food additives and other raw materials through a rotating mixing barrel. The mixing barrel is usually cylindrical and has a stirring blade or agitator installed inside. | The internal spiral blade rotates around the axis to push the food additives from both ends to the middle to achieve mixing. The pushing, shearing and convection of the blades make the food additives fully mixed in the mixing barrel. | Mixing is achieved through the shearing and convection of the paddle. The paddle mixer shears, convects and folds the raw materials such as food additives in the mixing barrel through the rotating motion of the paddle to achieve uniform mixing. | The food additive V-type mixer uses the bidirectional rotating blades in the V-shaped groove to push the food additives to the center, and then falls back along the groove wall to both ends to achieve mixing. |

| Features and applications | It is suitable for mixing food additives in various forms such as powder and granules, and is widely used in the mixing production process in the food industry. It is simple to operate and easy to control the mixing time and speed. | It is suitable for mixing powdered and granular food additives, with good mixing effect, stable operation, and can maintain the particle shape of the raw materials. | Suitable for mixing food additives in powder, granular and other forms, widely used in the mixing production process in the food industry. It can effectively mix food additives of different particle sizes, densities and shapes. | Simple operation, easy cleaning, high mixing efficiency, can quickly achieve uniform mixing of food additives, suitable for mixing food additives in the form of powders, granules, etc., to improve production efficiency and product quality. |

Food additive mixers are widely used in the food industry, covering many fields such as food processing, beverage production, baking industry, dairy production, condiment production, canned food production, etc. Through the function of the mixer, it can ensure that food additives are fully mixed and evenly mixed, improving product quality stability and production efficiency.

Food processing: Food additive mixer is used to mix various food additives, such as thickeners, emulsifiers, stabilizers, acidity regulators, antioxidants, etc. These additives play a role in improving food quality, enhancing food characteristics, and extending food shelf life during food processing.

Beverage production: In beverage production, food additive mixers are used to mix various flavorings, pigments, flavors and other additives to ensure that they are fully mixed and evenly mixed to make the beverage taste and color consistent.

Baking industry: In the baking industry, food additive mixers are used to mix flour improvers, leavening agents, thickeners and other additives to ensure the uniformity and stability of the dough and improve the quality of baked products.

Dairy production: In dairy production, food additive mixers are used to mix emulsifiers, stabilizers, humectants and other additives to ensure the stability and quality of dairy products.

Condiment production: Food additive mixers are often used in condiment production to mix various seasonings, spices, sauces, etc. to ensure uniform and stable flavor of condiments.

Canned food production: In canned food production, food additive mixers are used to mix various preservatives, acidity regulators, pigments and other additives to ensure the quality and shelf life of canned food.

The working principle of a food additive mixer is basically to mix different types of food additives with food base materials through stirring and mixing. The following is the working principle of a general food additive mixer:

Adding materials: First, add the food additives and food base materials to be mixed into the hopper or trough of the mixer respectively according to the formula requirements.

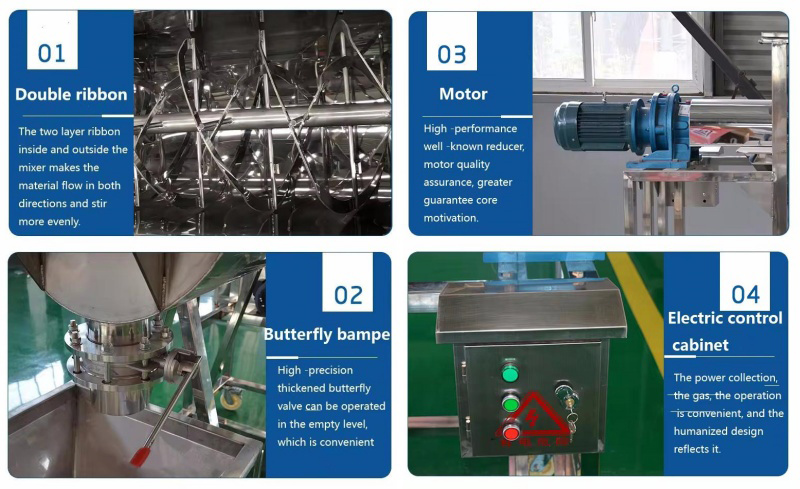

Stirring: Start the mixer, and the stirring device starts to rotate or vibrate to mix the additives and base materials. The mixing device usually consists of a rotating mixing blade, mixing arm or mixing spiral, which can fully mix the additives and base materials.

Dispersion: During the mixing process, the mixing device will generate shear force and turbulence to evenly disperse the additives in the base material. This helps ensure uniformity and stability of the additive.

Control parameters: During the mixing process, the degree and effect of mixing can be adjusted by controlling the mixer's speed, mixing time and other parameters. This helps achieve precise additive ratios and mixing requirements.

Mixing Complete:When mixing reaches the desired level, stop the mixer. At this point, the additives have been thoroughly mixed with the base material and have achieved the desired uniformity and stability.

Efficiency

The food additive mixer can quickly complete the mixing process, greatly improving production efficiency. It can stir and mix additives at high speed, saving time and labor costs.

Accuracy

Mixers can precisely control the proportions of additives and the degree of mixing, ensuring consistent quality and taste from batch to batch. This is crucial to maintaining product stability and quality.

Reliability

The food additive mixer is reasonably designed, with stable operating performance and reliable operation. It can operate stably for a long time and ensure the continuity and stability of the production process.

Uniformity

The mixer can evenly disperse food additives in the food base, ensuring the uniformity of the additives throughout the product. This helps improve the consistency of taste, color and aroma of the product.

Versatility

The food additive mixer is suitable for various types of food additives and can be used in different kinds of food processing processes. It has strong adaptability and flexibility and can meet the mixing needs of different products.

Cost-effectiveness

By using a food additive mixer, production efficiency can be improved and labor costs and production time can be reduced. At the same time, it can ensure product quality and stability, reduce waste and losses caused by uneven mixing of additives, thereby reducing production costs.

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

1. High or low material humidity:

For mixing materials with high humidity, you can choose a mixer with strong stirring and heating functions, such as a ribbon mixer or a paddle mixer.For materials with low mixing humidity, you can choose a mixer suitable for dry powder mixing, such as a V-type mixer or a spiral mixer.

2. Material selection:

In the food industry, mixers made of food-grade materials such as stainless steel are usually selected to ensure that the mixing process meets hygiene standards and has good corrosion resistance. If you need a mixer with higher material, you can choose a food additive mixer made of high manganese steel.

3. Selection of mixers with spray heads

The spray head is usually located on the top or side of the mixer and is connected to the liquid supply system through a pipe. You can adjust the amount of liquid added at any time according to actual needs, and adjust the humidity and adhesion of the material.

4. Mixing time:

The mixing time of our mixer is generally 8-20 minutes. The appropriate mixing time can ensure that the food additives are fully mixed with other raw materials and evenly distributed. Too short mixing time will result in uneven mixing, while too long mixing time may cause energy waste.

5. Mixing quality:

Mixing quality is directly related to the quality of the final product. The food additive mixer produced by Dahan Factory mixes materials very evenly, with a mixing rate of up to 99%.

Xinxiang Dahan food additive mixer price is $1000.00-$7,000.00/Set.

The price of a food additive mixer depends on several factors, including model, specification, brand, production capacity and additional functions.

First, small-capacity food additive mixers are cheaper, generally ranging from $1000.00-$3500.00/Set, while large, high-capacity mixers are more expensive. The general price range is between $3500.00-$7,000.00/Set.

Second, the price of ordinary food additive mixers ranges from several thousand to tens of thousands of RMB. High-end, highly automated mixers with special functions may cost more.

In addition, the purchase channel, after-sales service and accessories costs will also affect the overall price.

Finally, it is recommended that you fully understand your needs before purchasing, choose the appropriate model and brand, and consider the cost-effectiveness to ensure that you purchase a food additive mixer with stable performance and reasonable price.

Dahan Factory is the source mixer manufacturer with preferential prices. Please feel free to consult.

A food processing company faced the problem of unstable additive mixing effects while expanding production scale. In order to improve product quality and production efficiency, they decided to introduce a food additive mixer. Through communication with suppliers, they chose an advanced food additive mixing machine. The mixer uses advanced mixing and mixing technology to quickly and evenly mix different types of additives with food base materials to ensure product consistency and stability. At the same time, the mixer has a precise control system that can accurately adjust the proportion of additives and mixing time to ensure the product quality of each batch. Due to the efficiency and accuracy of the mixer, the company is able to accurately control the dosage of additives, reducing waste and losses, effectively reducing production costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.